-

[PR]

×

[PR]上記の広告は3ヶ月以上新規記事投稿のないブログに表示されています。新しい記事を書く事で広告が消えます。

-

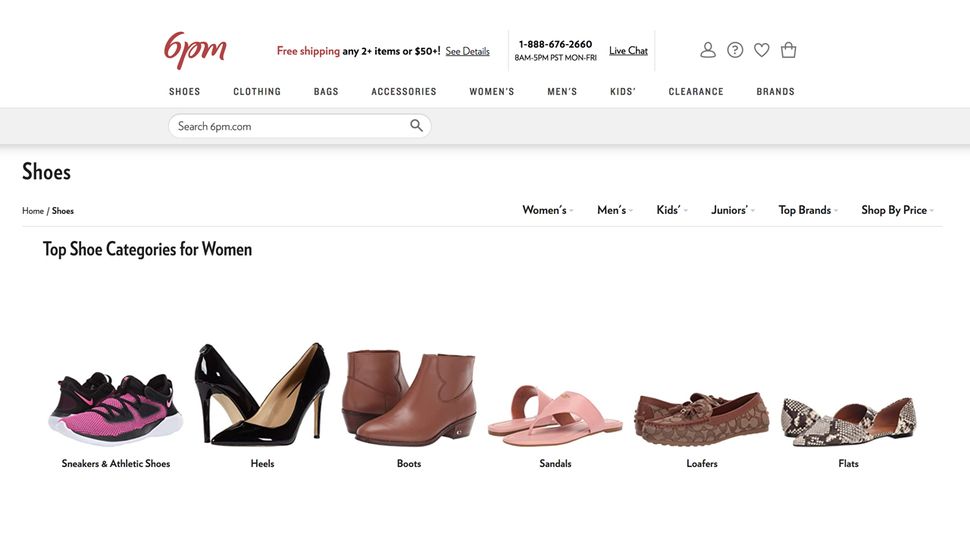

6pm: Best discount store

Private Label Shoes Manufacturer丨Shoes Supplier- XINDESHENG

Some big discounts for designer brands

Large inventory to choose from

Free shipping on large orders

If you are looking for outlet-level prices online, then 6pm is a good place to start your search. This is the sales base of Zappos and carries many of the same brands. However, since this is a specialty store, if you are willing to shop around for the things you like, you can buy much cheaper and much cheaper shoes. For private label shoes, you will find regular discounts, daily sales, and if you know where to find a large number of coupons, you can find them on the website.

The website itself is more standard than many competitors, but easy to navigate, and contains some bright, colorful product images. After entering the product page, you will see the shoes from many different angles, and you can use the drop-down menu on the right side of the page to change the size and color/style settings. There are no user reviews on the product page, so you really lack other information on each pair of shoes.

The downside is that the service you get from 6 pm on can't compare to Zappos at all. If you are indeed eligible for free shipping, but if you buy two or more pairs of shoes, or spend more than $50 (most of them will cost), the return will incur additional costs and there is no option to replace the shoes. You only need to pay to return the goods you bought before purchasing other goods. Customer support can be provided, but the service time is limited, and there is no VIP club or price matching promise (as you would expect from a direct sales store). Overall, you will like the price at 6pm, but make sure you want something before buying.

6pm user reviews and ratings

Has an A+ rating and is recognized by the Better Business Bureau

Score 3.5 by out of 5 Yelp

We looked at 55 comments around 6pm and found that they were widely acclaimed. People like cheap shoe prices, and many people are satisfied with what they pay for shopping at 6pm. Many people have emphasized the fact that you need to get the best deal quickly, and almost every user has commented on how good the range of discounted shoes is.

Most of the complaints around 6 pm, especially the BBB complaints, were focused on the delivery and transportation of the shoes. Some users reported delays in the delivery of the shoes, while others said that the delivery time was longer than the time posted on the website. One or two people said that the shoes they received were in poor condition and returned them. Overall, 6 pm is a good time to respond to complaints, as this is a common theme in user reviews.

PR -

How to customize shoes in shoe factory

Private Label Shoes Manufacturer丨Shoes Supplier- XINDESHENG

The following is a custom shoes process for our New De wins shoes.

This is a very complicated project custom shoe, it takes a lot of time to work. As for sample order, you can order 1 or 2 pairs of samples to check our work and shoes quality. However, after the sample is reviewed, a large amount of order has the minimum order (MOQ) requirements. Our minimum order is 1500 pairs of sneakers and 500 pairs of shoes. And the specific amount depends on different styles.

First, our shoes buyers need to find the most suitable outsole from hundreds of outsoled plants to make your shoes.

Second, the quality control department needs to go to the outsole factory to order a pair of outsole. After ordering the outsole, it takes a few days to open it. After getting the outsole, our technicians will check if this truly outsole is suitable for you to make shoes. If you can, our salesperson will send you the outsole to confirm. After confirming, our technicians need to open "style", then go to "Shoe Last" factory to open "shoes last" according to "Shoe Last Style". However, if the length and width of the outsole are not suitable, our quality control will need to re-order the outsole. It takes about a few days or a week.

Third, our purchaser needs to enter the material market to find all upper and lining materials and accessories. And all materials need to be taken back to the sample workshop for inspection. If there is an inappropriate material, our buyers need to find a suitable material again and again. This will take a few days. However, for some unique materials or leather materials, it may take 1-2 weeks.

Fourth, after the sample workshop approves all the correct materials, our quality control needs to order an accurate outsole color according to the upper material. At the same time, our workers will cut the fabric and then send it to the fitting factory for technical work, such as printing, embossed or seamless. Usually, printing, embossing or other technologies cannot be completed at a time, so our quality control needs multiple accessories to different accessories to make it perfect.

Finally, after all techniques are completed, our workers will start sewing to reinforce the outsole. You can see how much time our factory will make shoes samples, not to mention material costs and our salary and travel costs we should pay.

However, this is just the process of making shoes in the shoe factory, and has not launched a mass production order. That's why we need to customize the order of the shoes. Although the sample charges we make shoes may be slightly higher than the sample costs of other factories, the sample charges we have requires much lower than our actual sample costs. Therefore, if there is no big order, we will lose samples for you.

The following is some fees for shoes development:

※ Open mode fee: XX US dollar

※ Open time: xx usd

※ Material fee: three leather XX dollars

※ Printing fee: XX USD

※ Our purchase transportation fee: XX US dollar

※ Worker salary: each pair XX dollar

The sample fee does not include any mold fee.

After receiving the shoe sample, you can contact us for a specific modification if you need to modify it. We will make further modifications to develop better shoes that make you satisfied and even surprised!

If you are satisfied with the shoe sample, you can order our order. You can book on your website or exhibited at the Trade Exhibition. The general minimum order of our shoe factory is 1500 pairs of sneakers and 500 pairs of shoes. The specific quantity will depend on different styles and materials.

Article from: How to prepare for developing shoes

-

What Is OEM&ODM?

Private Label Shoes Manufacturer丨Shoes Supplier- XINDESHENG

The Definition Of Original Equipment ManufacturEr (OEM)

Content source: How To Prepare For Developing Shoes

OEM (Original Equipment Manufacturer) is often referred to as “contract manufacturing.” OEM is also known as “commissioned production,” “commissioned processing,” “famous brand manufacturing,” “production outsourcing,” etc. This kind of cooperation is called OEM that entrust other manufacturers of similar products to produce through contracting orders. The ordered products are bought out at a low price and directly labeled with their brand trademarks. The manufacturer who undertakes the processing task is called an OEM manufacturer, and the products they produce are OEM products.OEM refers to a current popular mode of production. A buyer provides equipment and technology. The manufacturer is responsible for production, workforce, and space, and a buyer is responsible for sales. OEM shoe manufacturers usually have a large and cheap labor force and provide the commission services for the manufacture and assembly of products required by the international market.

The OEM transaction can be viewed as a relationship between sales and purchase. From the buyer’s point of view, it is the act of outsourcing production and supplying to the market. From the supplier’s perspective, it is a transaction in which the supplier produces the brand products according to the buyer’s requirements. The buyer’s sales channel and brand and the supplier’s manufacturing constitute the product’s overall competitive advantages, bringing practical benefits to both sides.

The above statement is more professional. Here is an example for you to easier understand what OEM is.

OEM: A design, B production, A brand, A sales == OEM, OEM production, other people’s technology and brand, the factory only produces.

The Definition Of Original Design ManufacturEr (ODM)

ODM (Original Design Manufacturer), also referred to as “private labeling.” It relates to a production method in which a buyer entrusts a manufacturer to handle the whole process from design to production. The final product is labeled with the buyer’s trademark and sold by the buyer. In other words, it means that one company designs and produces a product according to the specifications of another company.

ODM refers to that a manufacturer design a product that other companies may adopt in some cases. Under the circumstances, does it require using the other companies’ brand name for production, or can the product be produced after the design is slightly modified? This allows other manufacturers to reduce their own development time. Manufacturers engaged in the design and manufacturing business are called ODM shoe manufacturers, and the products they produce are ODM products. There may offer manufacturers’ product design to the brand owner in a buyout or non-buyout.

The above statement is more professional. Here is an example to make it easier for you to understand what ODM is.

ODM: B design, B production, A brand, A sales == ODM. It is the factory’s products, other people’s brand.

OEM&ODM

Both OEM and ODM are cooperation models between the brand and the manufacturer in product design and manufacturing. OEM products are created for brand manufacturers. After production, the products can only be labeled with the brand name and can never be produced again with the manufacturer’s name. However, it depends on whether the brand enterprise has bought out the products’ copyright in terms of ODM products. If not, the manufacturer has the right to organize the production itself, as long as there is no design identification from the company.

OEM&ODM are commonplace in industrial society. Because of manufacturing costs, transportation convenience, save development time, or other aspects, well-known brand enterprises are generally willing to find OEM or ODM. When looking for the OEM or ODM, famous brand enterprises also have to bear many responsibilities. After all, the products are labeled with their brand. If the product quality is not good, it will impact the company’s brand. Therefore, the brand enterprises will undoubtedly carry out strict quality control during the commissioned processing.

Therefore, when you choose a China shoe factory, my advice is to find the shoe factory with full inspection personnel on the assembly line so that each pair of shoes can be inspected. It is better to ask a third-party shoe testing agency to test shoes in the shoe factory. In this way, you can know whether the shoe factory’s shoes are in line with the quality inspection standards. Therefore, we can guarantee the quality of shoes to the maximum.

In summary, the differences between OEM and ODM are shown in the following table, which helps you to select the type of factory you are looking for.

So, I believe you should understand what are OEM&ODM now. If you are interested in custom shoes and private label design shoes, you need to choose the shoe factory that provides OEM&ODM services. And our XIN DE SHENG SHOE FACTORY can provide OEM&ODM services. If you would like to custom shoes or look for private label shoe manufacturers, you can contact us by email: andy.h@topfactoryshoes.com.

-

DSW: Best Shoes Designer

Private Label Shoes Manufacturer丨Shoes Supplier- XINDESHENG

There are many kinds of shoes and boots, there are no other clothes on the scene.

Excellent clearance area, cheaper price

JLO collection is very suitable for browsing

DSW (Designer Shoes Warehouse) has many largest brands, including Nike, Steve Madden and UGG, so if you are looking for designer shoes, boots, sneakers or sandals, this is a good place for shopping. There is also a JLO collection that there is its own area on the website, and the scope is incredible. Although it may not match everyone's taste, there is no doubt that it's prestige. For the scope, DSW is one of the best. Private label shoes manufacturers are best.

The product page is very good, but it is not perfect. You will see a clear and clear product picture, and we can enjoy the fact that you can watch the shoes from all angles without the need to click. Size and shoes models and overall user ratings are listed on the right side of the page. We hope to see more feedback from customers, and more purchase suggestions, but overall results are good.

When you register a DSW's reward plan, you can earn points every $ 1. These points can be exchanged into gift cards, which is very good. DSW only provides free shipping services for VIP members, which is not the best choice. Although the exchange is free and can be completed within 60 days, the fee is required to pay $ 8.50 when returning. Another disadvantage of DSW is that although there are a large number of "clearance" parts on the website, it doesn't have a discount like other shoe stores we have seen. Although this is popular, it doesn't feel like a sales method you can find on other websites.

DSW User Reviews And Rating

Get a + rating through the Commercial Improvement Bureau

Grade 3.5 passed 5 consumer affairs

After reviewing more than 150 users commented on DSW, we noticed that customer service - especially in its physical store - is what people like. Many people also praised the benefits of the VIP program and pointed out that the discount from which far exceeded the "fees" of registered. You seem to have a lot of data, and DSW will send you coupons immediately after you register, but consider the discount you will get, this is not a bad thing.

The negative side is that some users pointed out that delivery is still not perfect enough, and customer service is not always effective on solving problems. Although most people praised customer service experience, some people pointed out that they didn't help. There are some problems in the VIP integral balance on its website, which has caused some negative comments. Overall, in DSW, users like the combination of online stores and physical stores, which makes it a strong item for the brand.

-

The most detailed process of running shoe production

Private Label Shoes Manufacturer丨Shoes Supplier- XINDESHENG

raw material

Running shoes are made of a variety of materials. The sole is divided into three layers: insole, midsole and outsole. The insole is a thin layer of artificial ethylene vinyl acetate (EVA). The midsole provides most of the cushioning, and their composition varies from manufacturer to manufacturer. Usually, it consists of polyurethane that surrounds another material (such as gel or liquid silicone), or polyurethane foam that is given a special brand name by the manufacturer. In some cases, polyurethane may surround a capsule of compressed air. The outsole is usually made of hard carbon rubber or softer blown rubber, although manufacturers use a variety of materials to create different textures on the outsole.

The rest of the covering is usually a synthetic material, such as artificial suede or nylon braid, with a plastic board or wood board that supports the shape. There may be leather coverings or nylon coverings with leather attachments. Cloth is usually limited to shoelaces installed through plastic eyelets, and nails have been replaced by an adhesive called an adhesive, which binds the various components together.

design

In the past 15 years, the design of running shoes has undergone tremendous changes, and the running shoes are now available in various styles and colors. Contemporary shoe designers focus on the anatomy and movement of the foot. They use cameras and computers to analyze factors such as limb movement, the impact of different terrain on impacts, and the impact of feet on impacts. Athletes are labeled pronators if their feet roll inward or supinators if their feet roll outward. Along with pressure points, friction patterns and impact forces, this information is entered into the computer, and the computer will calculate how to best adapt to these conditions. The designer will then test and develop prototypes based on the research on joggers and professional runners, so as to make the final design for the final mass production.

Running shoes may have as many as 20 parts, and the components listed below are the most basic. There are two main parts of a shoe: the upper (covering the top and sides of the foot) and the sole (contact with the foot).

When we move around the shoe in a clockwise direction, starting from the front of the upper part is the feather line, which forms the edge where the tip of the fender (or toe protector) meets the sole. Next comes the upper, which is usually a single piece of material that can shape the shoe and form the toe box. The shoe upper also has attachments, such as the throat, which contains the eyelids and shoelace parts. Under the shoelace part is the tongue, which can protect the foot from direct contact with the shoelace. Also attached to the upper along the sides of the shoe are reinforcements. If sewn on the outside of the shoe, these reinforcements are called saddles; if sewn on the inside, they are called bow bandages. Towards the rear of the shoe is the collar, and the upper usually has an Achilles tendon protector at the rear of the top of the shoe. Foxing shapes the back end of the shoe. Under it is a plastic cup to support the heel and heel.

There are three main parts at the bottom, the outsole, the midsole and the slope heel. Outsole provides

The first step in running shoe manufacturing involves die-cutting shoe parts with a cookie cutter. Next, stitch or glue together the parts that will form the upper part of the shoe. At this time, the upper does not look like a shoe, but a round cap. The extra material is called the permanent margin. After the shoe upper is heated and installed around the plastic mold called the shoe last, the insole, midsole and outsole are glued to the shoe upper.

The first step in running shoe manufacturing involves die-cutting shoe parts with a cookie cutter. Next, stitch or glue together the parts that will form the upper part of the shoe. At this time, the upper does not look like a shoe, but a round cap. The extra material is called the permanent margin. After the shoe upper is heated and installed around a plastic mold called the shoe last, the insole, midsole and outsole are glued to the shoe upper.

Traction and absorb shock. The midsole is designed for shock absorption, and the slope heel supports the heel. The insole is located inside the shoe and also contains arch support (sometimes called arch cookies).

manufacture

process

Shoemaking is a labor-intensive process, and the cost of producing many components of running shoes reflects the necessary skilled labor. Each stage of production requires precision and skills, and taking shortcuts to reduce costs may result in the production of inferior shoes. Some running shoes (called "slip shoes") do not have an insole board. Instead, a single layer of upper is wrapped around the top and bottom of the foot. However, most running shoes consist of an insole board, which is glued to the upper with cement. This section will focus on cement shoes.

Transport and stamping fabrics

1 First, the prepared synthetic material rolls and dyed, split and suede leather (used as part of fox skin) rolls to the factory.

2 Next, the shoe shape is stamped with a compression molding machine, and then it is cut in the form of a cookie cutter and various marks are engraved to guide the rest of the assembly. After packaging and labeling, these works will be sent to another part of the factory for stitching.

The complete running shoes have been tested for quality through the procedures established by the shoes and the United Trade Research Association. Defects inspected include poor durability, incomplete cement bonding, and incorrect stitching.

The complete running shoes have been tested for quality through the procedures established by the shoes and the United Trade Research Association. Defects inspected include poor durability, incomplete cement bonding, and incorrect stitching.

Assemble the upper and insole

3 Sewing or gluing the parts that make up the upper part of the shoe, and punching the shoelace hole. These components include feather threads, uppers, mudguards, throat (with eye and lace parts), tongue, saddle or bow bandages and other reinforcements, collars (with Achilles tendon protectors), tops and logos. At this point, the upper does not look like a shoe, but a round cap, because when the studs are glued to the sole, there will be excess material (called permanent edges) folded under the sole.

4 Next, sew the insole on the side of the upper. Then add the hardener to the heel area and toe box, and insert the insole board.

Attached upper and bottom

part

5 Heat the finished shoe upper and put it around the shoe. The shoe last is a plastic mold that forms the final shape of the shoe. Then, the automatic last helper pulls down the shoe upper. Finally, a cement nozzle is used to apply cement between the upper plate and the insole plate, and then the machine presses the two parts together to bond them together. The upper now has the exact shape of the finished shoe.

6 Layer and glue the pre-stamped and excavated form of the midsole and outsole or wedges to the upper. First, align and glue the outsole and midsole together. Next, align the outsole and midsole with the upper and place them above the heater to reactivate the cement. When the cement cools, the upper part and the lower part are joined together.

7 Take out the shoes from the last shoe and inspect it. Scrape off excess cement.

QC

Manufacturers can test their materials using procedures established by the Footwear and Joint Trade Research Association (SATRA), which provides equipment designed to test every element of shoes. After the shoe is completed, the factory's inspector will check for defects such as poor durability, incomplete cement bonding and stitching errors. Because running can cause injuries to the tendons and ligaments of the feet and legs, another test is currently being developed to evaluate the shock absorption performance of the shoes.

future

In the near future, experts predict that current design and manufacturing processes will continue to improve, rather than major breakthroughs. In the next ten years, the size of sports shoes will become a worldwide standard. Designers will continue to seek lighter weight materials to provide better support and stability when the gel and air system are further used. Electronic components will also be built into running shoes so that microchips can be used to measure information about physical characteristics and development, and then download them to a computer. Another feature that has begun to appear is a battery-powered lighting system to accommodate jogging at night. As consumers continue to spend millions of dollars on comfortable running shoes.

read more:Top Private Label Running Shoe Manufacturers And Suppliers